Plastic PCR (Post-Consumer Recycled) Materials

What is Plastic PCR?

Plastic PCR refers to plastic that has been recycled from post-consumer waste and reprocessed into new packaging materials. By incorporating PCR plastic into their packaging, brands can significantly reduce their reliance on virgin plastic, divert waste from landfills, and support the development of a circular economy. PCR is an essential step towards sustainability, allowing brands to lessen their carbon footprint and align with environmentally conscious consumer expectations.

Benefits of Plastic PCR Packaging

- Reduced Plastic Consumption: Using PCR plastic mitigates the creation of new plastic, preventing additional waste from entering the environment and conserving resources used in the production of virgin materials.

- Lower Carbon Footprint: PCR plastic reduces the energy, water, and fossil fuels needed to produce packaging, leading to fewer greenhouse gas emissions and contributing to global sustainability goals.

• Boosting Brand Sustainability: Packaging made from PCR plastic allows brands to communicate their commitment to reducing plastic waste and offer products that resonate with today’s environmentally conscious consumers.

Applications of PCR Plastic in Packaging

Plastic PCR materials are versatile and suitable for a wide range of packaging applications across industries, including:

- Personal Care & Cosmetics: Brands in the beauty and personal care sectors can utilize PCR plastic for eco-friendly packaging solutions, such as bottles, jars, and tubes for skincare, haircare, and cosmetic products.

- Household Products: PCR plastic is an ideal solution for packaging household cleaning products, laundry detergents, and other household items, offering both functionality and sustainability.

- Pharmaceutical & Nutraceutical Packaging: The healthcare industry can benefit from using PCR plastic to safely package over-the-counter medications, vitamins, supplements, and other wellness products.

- Food & Beverage Packaging: Food and beverage brands can reduce their environmental impact by opting for PCR plastic packaging that maintains product freshness while reducing the consumption of new plastic.

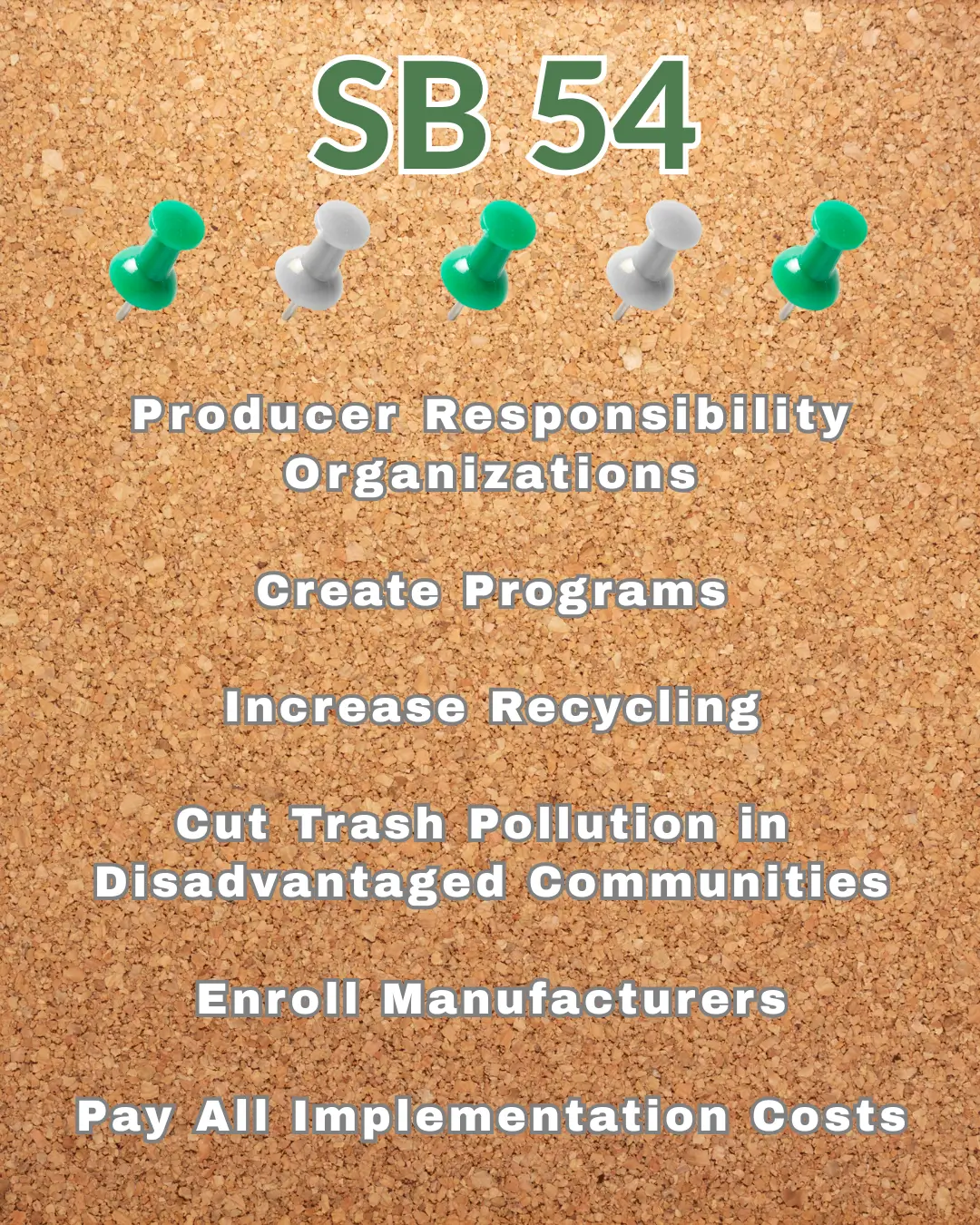

SB54 Requirements: A Push Toward Sustainable Packaging

Key SB54 Requirements:

- Minimum Recycled Content:

By 2032, SB54 requires that all packaging materials sold in California contain at least 65% recycled content, with an emphasis on reducing the use of virgin plastic. This means that brands must adopt more sustainable materials, like Plastic PCR (Post-Consumer Recycled) plastic, to meet these standards and reduce the environmental impact of their products.

- Plastic Packaging Reduction:

The law requires a 25% reduction in single-use plastic packaging within the next decade. Brands must rethink their packaging designs and explore alternatives that minimize plastic use, such as concentrating formulations or opting for materials with higher recyclability.

- Producer Responsibility:

Under SB54, producers are now responsible for the end-of-life management of their packaging. This includes financing recycling programs and ensuring that packaging can be reused or recycled through California’s waste management system.

- Recycling and Compostability Standards:

SB54 sets strict criteria for materials to be considered recyclable or compostable. Brands must design packaging that can be efficiently processed through California’s recycling infrastructure, further pushing the shift toward materials like PCR plastic that are more easily integrated into the recycling stream.

How Plastic PCR Helps Brands Meet SB54 Compliance

High-Quality Performance & Customization

Let’s Work Together to Reduce Plastic Waste

Frequently Asked Questions

1. What is Plastic PCR?

Plastic PCR (Post-Consumer Recycled) refers to plastic materials that have been recovered from consumer waste, cleaned, and reprocessed into new packaging components. It reduces the need for virgin plastic and supports a circular economy.

2. What are the environmental benefits of using PCR plastic?

Using PCR plastic significantly reduces:

- Dependence on fossil fuel-based virgin plastic

- Greenhouse gas emissions during production

- Waste entering landfills or oceans

- Water and energy consumption in the supply chain

3. How does PCR plastic support compliance with SB54 in California?

SB54 mandates that packaging sold in California must contain at least 65% recycled content by 2032 and reduce overall plastic use by 25%. By using PCR plastic, brands meet recycled content goals and show active participation in reducing plastic waste.

4. Is PCR plastic as durable and effective as virgin plastic?

Yes. At NuGen Packaging, our PCR plastic materials are engineered to meet the same performance standards as virgin plastic—including barrier protection, strength, and shelf appeal.

5. What types of products can use PCR plastic packaging?

PCR plastic is ideal for:

- Personal care & cosmetics (tubes, bottles, jars)

- Household products (cleaners, detergents)

- Pharmaceutical & nutraceutical items (vitamin bottles, OTC meds)

- Food & beverage packaging where appropriate

6. Can PCR plastic be customized to match my brand’s aesthetic?

Absolutely. We offer a wide range of customization options including custom molds, sizes, color-matching, and pressure-sensitive labels to support your branding and product differentiation.

7. Is PCR plastic recyclable again after use?

Yes, PCR plastic is usually recyclable, depending on local recycling capabilities. For maximum circularity, it’s important to design packaging that adheres to recycling guidelines.

8. Does using PCR plastic cost more than virgin plastic?

Costs can vary depending on supply and market demand, but many brands find the long-term value, such as regulatory compliance, brand alignment with sustainability, and customer loyalty, well worth the investment.

9. How can NuGen Packaging help me transition to PCR plastic?

We provide strategic support at every step, from material selection and compliance guidance to packaging design and production. Our team ensures that your PCR packaging not only meets performance and branding needs but is also aligned with sustainability mandates like SB54.

10. What is the minimum PCR content I should be targeting today?

While SB54 sets a goal of 65% by 2032, many brands are starting with 25-50% PCR content to balance sustainability with performance and cost. We can help you develop a roadmap that meets today’s needs and future-proof your packaging.