Glass Bottle Molding: Sustainable Solutions with Recycled Glass (Cullet)

The Glass Bottle Molding Process

Glass bottle molding begins with a precise mix of raw materials, including silica sand, soda ash, limestone, and cullet. The inclusion of cullet, often in high percentages, not only reduces the amount of raw materials needed but also lowers the melting temperature, which conserves energy and cuts down on CO2 emissions.

- Batching and Melting: The raw materials, including cullet, are carefully measured and combined in a batch. This mixture is then fed into a furnace, where it is heated to approximately 1,600°C (2,912°F) to form molten glass. The higher the percentage of cullet, the lower the energy required to melt the batch, contributing to a more sustainable manufacturing process.

- Forming: Once the molten glass reaches the ideal consistency, it is delivered to the molding section. Here, molten glass is cut into “gobs” and dropped into molds. There are two primary molding techniques:

- Blow-and-blow molding: This method is used for bottles with narrow openings, such as beverage bottles. It involves shaping the glass by blowing air into the mold to form the bottle’s shape.

- Press-and-blow molding: Typically used for wide-mouth containers, this technique presses the molten glass into the initial mold shape and then blows it into the final form.

- Annealing: After forming, the glass containers undergo annealing, a controlled cooling process that removes internal stresses, ensuring durability and strength.

- Quality Control and Finishing: Once cooled, each glass bottle is inspected for defects and polished if necessary.

The Role of Cullet (Recycled Glass)

Incorporating cullet into the glass manufacturing process not only helps reduce waste but also offers significant environmental benefits:

- Energy Conservation: Every 10% increase in cullet usage can reduce energy consumption by 2-3%, resulting in a lower carbon footprint.

- Reduced Emissions: Using cullet reduces CO2 emissions during the melting process.

- Waste Reduction: Cullet keeps tons of glass out of landfills, creating a closed-loop system where old glass is transformed into new bottles again and again.

We continually push for higher cullet percentages in our glass production to support a more circular economy while delivering high-quality, sustainable packaging solutions.

Contact us to learn more about how our glass packaging can enhance your brand while reducing your environmental footprint.

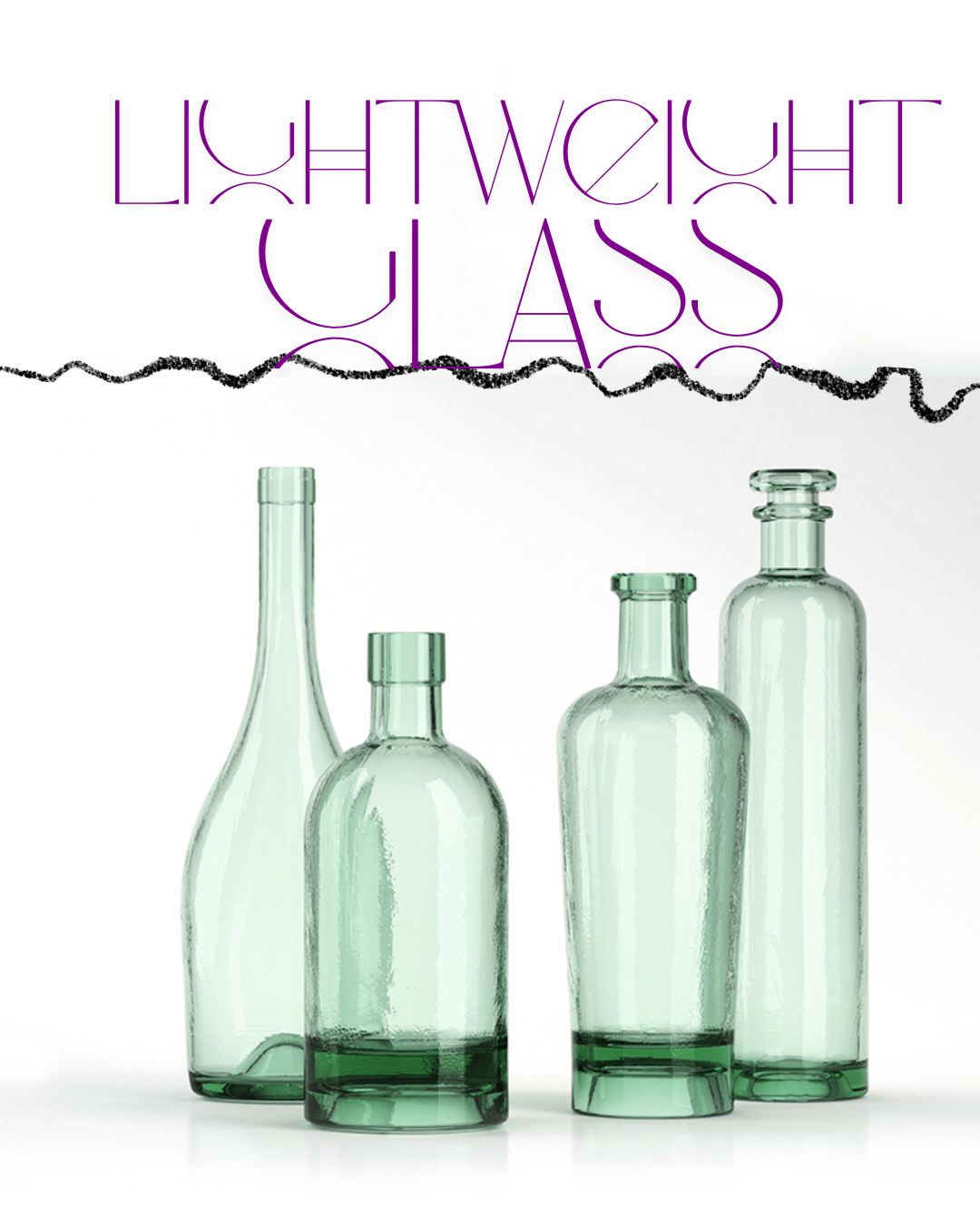

Lightweighting Glass: Reducing Environmental Impact Without Compromising Quality

The Benefits of Lightweighting Glass

- Lower Carbon Footprint: By reducing the weight of glass bottles and jars, we decrease the amount of raw materials required in production and significantly cut down on energy consumption during manufacturing. This also results in fewer CO2 emissions, supporting your brand’s sustainability goals.

- Reduced Transportation Costs: Lighter glass containers require less fuel for transportation, leading to lower shipping costs and further reducing the carbon footprint. This is particularly beneficial for brands looking to minimize their environmental impact throughout the supply chain.

- Material Efficiency: Lightweighting uses advanced design techniques to optimize the structure of glass bottles, ensuring they remain as strong and functional as traditional containers. The process involves fine-tuning glass distribution during molding to reduce thickness in non-critical areas while reinforcing key structural points.

- Maintaining Aesthetics and Functionality: Despite the reduced material use, lightweight glass containers maintain the premium look and feel that glass is known for. They continue to offer excellent barrier properties, protecting products from contamination and extending shelf life.

Lightweighting and Sustainability

Incorporating lightweighting into glass production aligns with our dedication to reducing waste and improving efficiency across the packaging lifecycle. It complements our focus on using cullet (recycled glass), further lowering the environmental impact of glass production. By combining these approaches, we deliver sustainable packaging solutions that help brands achieve their eco-friendly targets without compromising on quality or consumer appeal.

Partner with NuGen Packaging to explore how lightweighting glass can elevate your packaging strategy while contributing to a greener future.

Decorating and Labeling Glass: Enhancing Brand Appeal with Customization

In addition to offering sustainable glass packaging solutions, NuGen Packaging provides a wide range of decorating and labeling options to elevate the aesthetic appeal of your glass containers. Whether you’re looking to create a sleek, minimalistic look or an intricate, eye-catching design, our customization services can help your product stand out on the shelf while maintaining its eco-friendly credentials.

Custom Decorating Techniques

- Screen Printing: One of the most popular methods for decorating glass, screen printing allows for vibrant, long-lasting designs. Ideal for high-end and luxury products, this technique uses inks that are baked onto the surface of the glass, ensuring durability and resistance to wear.

- Frosting and Etching: For a premium, sophisticated look, frosting or etching adds texture to the glass surface. This technique can be used to create a subtle, matte finish or intricate designs that offer a tactile element to your packaging.

- Hot Stamping: This decorative method applies metallic foils, such as gold or silver, to the glass surface. Hot stamping adds a luxurious, reflective quality to your packaging, making your product visually striking.

- Spray Coating: Customize your glass containers with spray coatings in a variety of colors and finishes, from matte to glossy. This technique can also provide additional UV protection to preserve sensitive products.

Labeling Options

- Pressure-Sensitive Labels (PSL): A flexible solution for many glass packaging types, PSL offers high-quality printing with the ability to include complex designs, textures, and finishes. These labels can be applied quickly and conform seamlessly to the container, ensuring a premium look.

- Shrink Sleeves: Offering 360-degree coverage, shrink sleeves are an excellent option for fully wrapping your glass container with bold, colorful designs. This method maximizes branding space and is especially effective for niche and specialty products.

- Direct Print Labels: For a more integrated look, direct print labels are applied directly onto the glass surface, offering a seamless, polished appearance. These labels are durable and resistant to moisture, ensuring longevity throughout the product’s lifecycle.

Sustainable Labeling Solutions

As part of our commitment to sustainability, we offer eco-friendly labeling options that complement your glass packaging. These include labels made from recyclable materials or using water-based adhesives, ensuring that your entire packaging solution remains environmentally responsible.

At NuGen Packaging, we believe that your packaging is an extension of your brand’s identity. With our wide range of decorating and labeling options, you can create glass containers that not only reflect your sustainability values but also captivate consumers with stunning visual appeal.

Frequently Asked Questions

1. What materials are used to mold glass bottles?

2. How does recycled glass (cullet) make glass packaging more sustainable?

Cullet significantly reduces energy consumption and CO2 emissions during production. For every 10% increase in cullet usage, energy usage drops by 2–3%, helping reduce your brand’s carbon footprint while keeping glass out of landfills.

3. What is the difference between blow-and-blow and press-and-blow molding?

- Blow-and-blow is used for bottles with narrow necks (e.g., beverage bottles), where air is used to shape the bottle in two steps.

- Press-and-blow is used for wide-mouth containers and involves pressing molten glass into a preform before blowing it into the final shape.

Both methods ensure structural integrity and consistency in production.

4. What is the annealing process in glass manufacturing?

Annealing is a controlled cooling process that relieves internal stresses in molded glass containers. This step ensures the glass bottles are durable and less prone to breakage during filling, labeling, or shipping.

5. What is lightweighting, and how does it benefit glass packaging?

Lightweighting reduces the overall weight of glass containers without sacrificing durability. Benefits include:

- Reduced raw material use

- Lower energy consumption

- Decreased shipping costs and carbon emissions

- Maintained premium aesthetic and protective qualities

6. Will lightweight glass compromise the strength or shelf appeal of my packaging?

No. Lightweight glass bottles are engineered to retain the strength, barrier protection, and luxury feel of traditional glass while improving environmental performance and efficiency.

7. What decorating options are available for glass bottles?

NuGen Packaging offers a range of custom decoration techniques, including:

- Screen printing for long-lasting branding

- Frosting and etching for texture and elegance

- Hot stamping with metallic foils for a premium finish

- Spray coating for color and UV protection

8. What are my labeling options for glass containers?

You can choose from:

- Pressure-sensitive labels (PSL) for flexibility and quality

- Shrink sleeves for 360° branding coverage

- Direct print labels for seamless, durable branding

All labeling methods can be tailored to reflect your sustainability goals and visual identity.

9. Do you offer sustainable labeling solutions?

Yes. We offer eco-friendly labels made from recyclable materials and water-based adhesives, ensuring your entire glass packaging system supports your environmental values.

10. How can glass packaging support a circular economy?

Glass is 100% recyclable and can be remelted infinitely without loss of quality. By incorporating high levels of cullet and designing for recyclability, NuGen Packaging helps brands close the loop and contribute to a more circular packaging ecosystem.