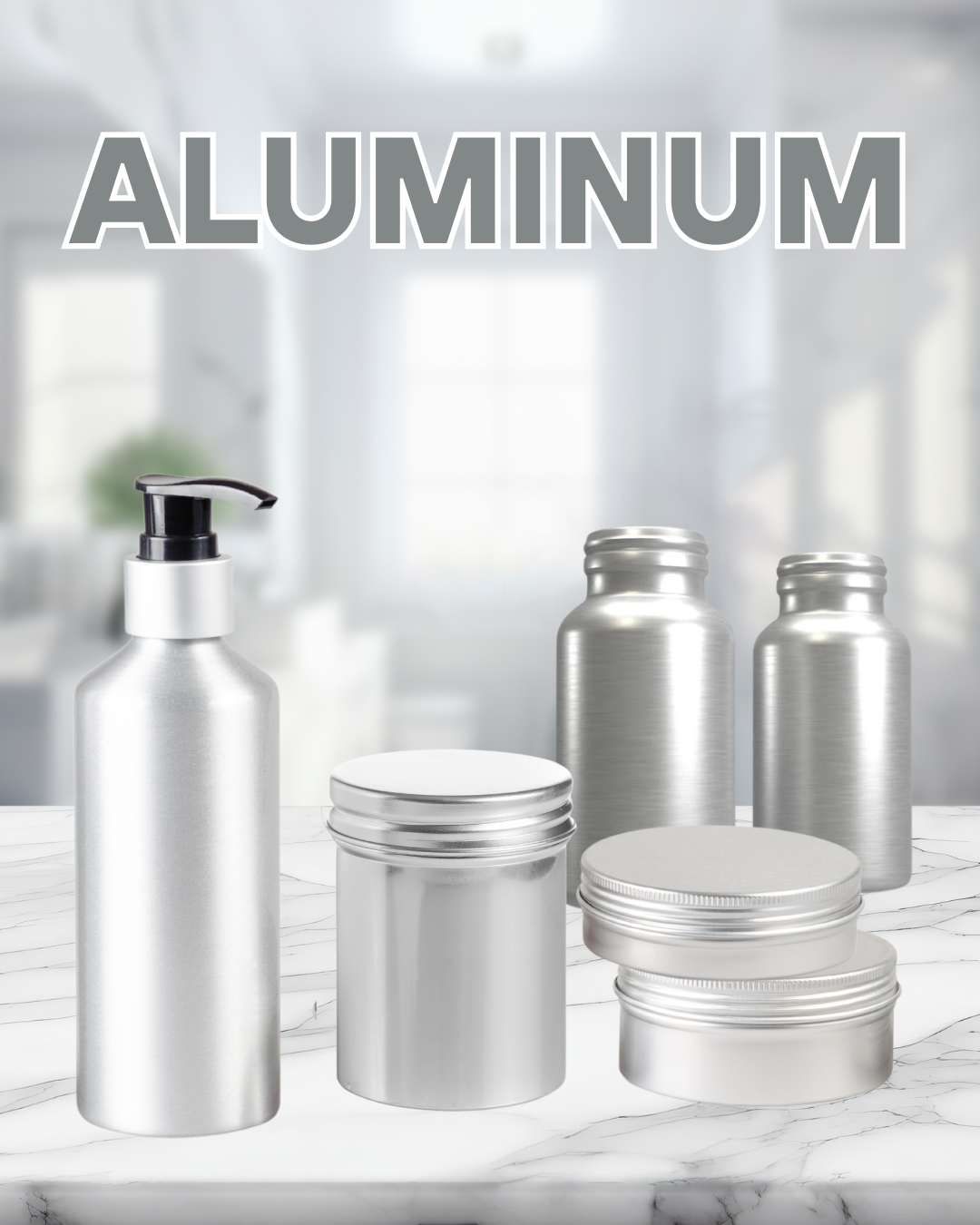

Aluminum Products

Aluminum Bottles & Jars

- Raw Aluminum Slug: A precisely cut aluminum slug forms the base of the product.

- Impact Extrusion: High pressure transforms the slug into a bottle or jar, creating a single, joint-free piece.

- Necking Process: The neck of the bottle or jar is shaped to fit closures, ensuring product protection and preventing leaks.

4. Surface Treatment, Decoration & Dry Offset Printing: After formation, bottles and jars can be treated with anodizing or powder coating to enhance durability. Dry offset printing enables the application of vibrant, full-color graphics, allowing for visually striking branding without compromising the aluminum’s integrity.

Labeling Options

- Pressure-Sensitive Labels (PSL)

Pressure-sensitive labels (PSL) offer a flexible solution for aluminum packaging, providing high-quality printing with the ability to include complex designs, textures, and finishes. These labels adhere to the surface of aluminum bottles and jars without the need for heat or water, ensuring easy application. PSL can be customized to conform seamlessly to the container’s shape, delivering a premium and professional appearance. Whether you’re aiming for bold colors, metallic accents, or intricate patterns, PSL can help you achieve the exact look you want for your brand. - Shrink Sleeves

Shrink sleeves provide 360-degree coverage, making them a popular choice for fully wrapping aluminum bottles or jars with vibrant, bold designs. This method allows for maximum branding space and is perfect for showcasing intricate artwork or creating a cohesive, attention-grabbing visual. Shrink sleeves are particularly effective for niche and specialty products, as they offer flexibility in design and protection against scratches or abrasions during transportation and handling. With their ability to conform to curved surfaces, shrink sleeves ensure total design flexibility on aluminum containers.

Aluminum Collapsible Tubes

Aluminum collapsible tubes provide a flexible yet sturdy packaging option, commonly used for pharmaceuticals, cosmetics, and food products. These tubes are designed to collapse as the product is dispensed, preventing air from re-entering the packaging and preserving the product’s freshness.

Key benefits of aluminum collapsible tubes include:

Product Evacuation: Aluminum tubes are more efficient at evacuating product compared to plastic tubes, allowing users to access nearly all of the product inside with less effort. This reduces product waste and offers a more cost-effective solution for consumers.

Protective Barrier: They offer a high level of protection against contaminants, light, and oxygen, preserving the product’s quality.

Customizable Design: The surface of aluminum tubes can be decorated with dry offset printing for high-quality, full-color designs, allowing for eye-catching branding and messaging.

Eco-Friendly: Like aluminum bottles and jars, collapsible tubes are recyclable, making them a sustainable packaging solution that helps minimize plastic waste.

Aluminum’s Sustainability

Infinitely Recyclable

One of the most significant sustainability advantages of aluminum is that it is infinitely recyclable. Unlike many other materials that degrade in quality over time, aluminum can be recycled again and again without losing its structural integrity or performance. In fact, nearly 75% of all aluminum ever produced is still in use today. This helps reduce the need for virgin material, conserving natural resources and energy.

Energy Efficiency in Recycling

Recycling aluminum requires 95% less energy than producing new aluminum from raw materials. This massive reduction in energy use translates to lower greenhouse gas emissions and a much smaller carbon footprint. By choosing aluminum packaging, brands and consumers alike are actively contributing to a more sustainable, energy-efficient supply chain.

Circular Economy Contribution

Aluminum’s ability to be recycled in a closed loop makes it a cornerstone of the circular economy. In a circular system, materials are kept in use for as long as possible, reducing waste and maximizing resources. Aluminum bottles, jars, and tubes are perfect candidates for this system, as they can be returned, recycled, and reformed into new packaging without compromising quality.

Lightweight, Reducing CO2 Emissions

Aluminum is known for its lightweight properties, which provide additional sustainability benefits. Its low weight reduces transportation costs and fuel consumption, leading to fewer CO2 emissions during transit. This makes aluminum an excellent choice for companies aiming to lower their environmental footprint throughout the supply chain.

Protective & Efficient Material

Aluminum’s superior barrier properties help extend product shelf life by protecting contents from light, air, and moisture. This leads to less product spoilage and waste, further enhancing its environmental benefits. Packaging efficiency plays a crucial role in sustainability, and aluminum’s ability to keep products fresh longer contributes to reducing overall waste.

Frequently Asked Questions

1. What makes aluminum bottles and jars different from other packaging materials?

Aluminum bottles and jars can be made using a monoblock extrusion process, which creates a seamless, joint-free structure. This provides exceptional durability, superior product protection, and an upscale look, making them ideal for liquids, creams, and sensitive formulations.

2. Is aluminum packaging recyclable?

Yes. Aluminum is one of the most sustainable packaging materials available. It is infinitely recyclable without degradation, and nearly 75% of all aluminum ever produced is still in use today. Choosing aluminum helps reduce plastic waste and supports a circular economy.

3. How is the aluminum bottle or jar formed?

The process starts with a raw aluminum slug that is impact-extruded under high pressure to form the container. The neck is then shaped to fit closures, and surface treatments or printing are applied for durability and branding.

4. What surface decoration options are available?

Aluminum bottles and jars can be customized with anodizing, powder coating, or dry offset printing. These techniques allow for premium, full-color branding without compromising the material’s recyclability.

5. What labeling options can I choose for my aluminum packaging?

We offer several labeling options:

- Pressure-Sensitive Labels (PSL) for precise application with high design flexibility.

- Shrink Sleeves for full 360-degree coverage and bold visual branding.

Each method provides excellent adhesion and visual impact on aluminum surfaces.

6. Are aluminum collapsible tubes a good option for creams and gels?

Absolutely. Aluminum collapsible tubes are ideal for pharmaceuticals, cosmetics, and food products. They collapse as the product is used, preventing air from re-entering the tube, which helps maintain freshness and reduce waste.

7. What are the sustainability benefits of using aluminum?

Aluminum offers multiple sustainability advantages:

- Infinitely recyclable with no loss of quality.

- 95% less energy required for recycling vs. producing new aluminum.

- Lightweight, which reduces CO₂ emissions during transport.

- Superior barrier protection, minimizing product spoilage.

8. Can I use aluminum packaging for food, supplements, or personal care products?

Yes. Our aluminum bottles, jars, and tubes are suitable for a wide range of applications, including nutraceuticals, pharmaceuticals, personal care, and food products. They are produced with food-grade linings.

9. How does aluminum packaging contribute to a circular economy?

Aluminum fits perfectly into a closed-loop recycling system. After use, containers can be recycled and reprocessed into new packaging without any loss in performance, keeping materials in use and reducing waste.

10. Is aluminum packaging more expensive than plastic?

While aluminum may have a higher upfront cost, its long-term value is significant. Brands benefit from enhanced shelf appeal, reduced product waste, and strong sustainability messaging, all of which drive customer loyalty and support regulatory compliance.